what is the rubber o-ring for and what kind of rubber is used in o-rings ?

what is the rubber o-ring for and what kind of rubber is used in o-rings ?

Primum -please oring AS568 reprehendo "

| AS568 MENSURA | Nominal ID | Nominal C/S | Id est in pollices mensurae | ± ID | Mensurae CS in pollices | ± CS | Mensurae ID in mm | ± ID | Mensurae CS in mm | ± C/S | ||||||||||

| -1 | 1/32 | 1/32 | 0.029 | 0.004 | 0.041 | 0.003 | 0.74 | 0.10 | 1.02 | 0.08 | ||||||||||

| -2 | 3/64 | 3/64 | 0.041 | 0.004 | 0.041 | 0.003 | 1.07 | 0.10 | 1.27 | 0.08 | ||||||||||

| -3 | 1/16 | 1/16 | 0.093 | 0.004 | 0.093 | 0.003 | 1.42 | 0.10 | 1.52 | 0.08 | ||||||||||

| -4 | 5/64 | 1/16 | 0.093 | 0.005 | 0.093 | 0.003 | 1.78 | 0.13 | 1.78 | 0.08 | ||||||||||

| -5 | 3/32 | 1/16 | 0.101 | 0.005 | 0.093 | 0.003 | 2.57 | 0.13 | 1.78 | 0.08 | ||||||||||

| -6 | 1/8 | 1/16 | 0.114 | 0.005 | 0.093 | 0.003 | 2.90 | 0.13 | 1.78 | 0.08 | ||||||||||

| -7 | 5/32 | 1/16 | 0.145 | 0.005 | 0.093 | 0.003 | 3.68 | 0.13 | 1.78 | 0.08 | ||||||||||

| -8 | 3/16 | 1/16 | 0.176 | 0.005 | 0.093 | 0.003 | 4.47 | 0.13 | 1.78 | 0.08 | ||||||||||

| -9 | 7/32 | 1/16 | 0.208 | 0.005 | 0.093 | 0.003 | 5.28 | 0.13 | 1.78 | 0.08 | ||||||||||

| -10 | 1/4 | 1/16 | 0.239 | 0.005 | 0.093 | 0.003 | 6.07 | 0.13 | 1.78 | 0.08 | ||||||||||

| -11 | 5/16 | 1/16 | 0.301 | 0.005 | 0.093 | 0.003 | 7.65 | 0.13 | 1.78 | 0.08 | ||||||||||

| -12 | 3/8 | 1/16 | 0.364 | 0.005 | 0.093 | 0.003 | 9.25 | 0.13 | 1.78 | 0.08 | ||||||||||

| -13 | 7/16 | 1/16 | 0.426 | 0.005 | 0.093 | 0.003 | 10.82 | 0.13 | 1.78 | 0.08 | ||||||||||

| -14 | 1/2 | 1/16 | 0.489 | 0.005 | 0.093 | 0.003 | 12.42 | 0.13 | 1.78 | 0.08 | ||||||||||

| -15 | 9/16 | 1/16 | 0.551 | 0.007 | 0.093 | 0.003 | 14.00 | 0.18 | 1.78 | 0.08 | ||||||||||

| -16 | 5/8 | 1/16 | 0.614 | 0.009 | 0.093 | 0.003 | 15.60 | 0.23 | 1.78 | 0.08 | ||||||||||

| -17 | 11/16 | 1/16 | 0.676 | 0.009 | 0.093 | 0.003 | 17.17 | 0.23 | 1.78 | 0.08 | ||||||||||

| -18 | 3/4 | 1/16 | 0.739 | 0.009 | 0.093 | 0.003 | 18.77 | 0.23 | 1.78 | 0.08 | ||||||||||

| -19 | 13/16 | 1/16 | 0.801 | 0.009 | 0.093 | 0.003 | 20.35 | 0.23 | 1.78 | 0.08 | ||||||||||

| -20 | 7/8 | 1/16 | 0.864 | 0.009 | 0.093 | 0.003 | 21.95 | 0.23 | 1.78 | 0.08 | ||||||||||

| -21 | 15/16 | 1/16 | 0.926 | 0.009 | 0.093 | 0.003 | 23.52 | 0.23 | 1.78 | 0.08 | ||||||||||

| -22 | 1 | 1/16 | 0.989 | 0.013 | 0.093 | 0.003 | 25.12 | 0.25 | 1.78 | 0.08 | ||||||||||

| -23 | 1 1/16 | 1/16 | 1.051 | 0.013 | 0.093 | 0.003 | 26.70 | 0.25 | 1.78 | 0.08 | ||||||||||

| -24 | 1 1/8 | 1/16 | 1.114 | 0.013 | 0.093 | 0.003 | 28.30 | 0.25 | 1.78 | 0.08 | ||||||||||

| -25 | 1 3/16 | 1/16 | 1.176 | 0.011 | 0.093 | 0.003 | 29.87 | 0.28 | 1.78 | 0.08 | ||||||||||

| -26 | 1 1/4 | 1/16 | 1.239 | 0.011 | 0.093 | 0.003 | 31.47 | 0.28 | 1.78 | 0.08 | ||||||||||

| -27 | 1 5/16 | 1/16 | 1.301 | 0.011 | 0.093 | 0.003 | 33.05 | 0.28 | 1.78 | 0.08 | ||||||||||

| -28 | 1 3/8 | 1/16 | 1.364 | 0.013 | 0.093 | 0.003 | 34.65 | 0.33 | 1.78 | 0.08 | ||||||||||

| -29 | 1 1/2 | 1/16 | 1.489 | 0.013 | 0.093 | 0.003 | 37.82 | 0.33 | 1.78 | 0.08 | ||||||||||

| -30 | 1 5/8 | 1/16 | 1.614 | 0.013 | 0.093 | 0.003 | 41.00 | 0.33 | 1.78 | 0.08 | ||||||||||

| -31 | 1 3/4 | 1/16 | 1.739 | 0.014 | 0.093 | 0.003 | 44.17 | 0.38 | 1.78 | 0.08 | ||||||||||

| -32 | 1 7/8 | 1/16 | 1.864 | 0.014 | 0.093 | 0.003 | 47.35 | 0.38 | 1.78 | 0.08 | ||||||||||

| -33 | 2 | 1/16 | 1.989 | 0.018 | 0.093 | 0.003 | 50.52 | 0.46 | 1.78 | 0.08 | ||||||||||

| -34 | 2 1/8 | 1/16 | 2.114 | 0.018 | 0.093 | 0.003 | 53.70 | 0.46 | 1.78 | 0.08 | ||||||||||

| -35 | 2 1/4 | 1/16 | 2.239 | 0.018 | 0.093 | 0.003 | 56.87 | 0.46 | 1.78 | 0.08 | ||||||||||

| -36 | 2 3/8 | 1/16 | 2.364 | 0.018 | 0.093 | 0.003 | 60.05 | 0.46 | 1.78 | 0.08 | ||||||||||

| -37 | 2 1/2 | 1/16 | 2.489 | 0.018 | 0.093 | 0.003 | 63.22 | 0.46 | 1.78 | 0.08 | ||||||||||

| -38 | 2 5/8 | 1/16 | 2.614 | 0.018 | 0.093 | 0.003 | 66.40 | 0.51 | 1.78 | 0.08 | ||||||||||

| -39 | 2 3/4 | 1/16 | 2.739 | 0.018 | 0.093 | 0.003 | 69.57 | 0.51 | 1.78 | 0.08 | ||||||||||

| -40 | 2 7/8 | 1/16 | 2.864 | 0.018 | 0.093 | 0.003 | 72.75 | 0.51 | 1.78 | 0.08 | ||||||||||

| -41 | 3 | 1/16 | 2.989 | 0.024 | 0.093 | 0.003 | 75.92 | 0.61 | 1.78 | 0.08 | ||||||||||

| -42 | 3 1/4 | 1/16 | 3.239 | 0.024 | 0.093 | 0.003 | 82.27 | 0.61 | 1.78 | 0.08 | ||||||||||

| -43 | 3 1/2 | 1/16 | 3.489 | 0.024 | 0.093 | 0.003 | 88.62 | 0.61 | 1.78 | 0.08 | ||||||||||

| -44 | 3 3/4 | 1/16 | 3.739 | 0.027 | 0.093 | 0.003 | 94.97 | 0.69 | 1.78 | 0.08 | ||||||||||

| -45 | 4 | 1/16 | 3.989 | 0.027 | 0.093 | 0.003 | 101.32 | 0.69 | 1.78 | 0.08 | ||||||||||

| -46 | 4 1/4 | 1/16 | 4.239 | 0.030 | 0.093 | 0.003 | 107.67 | 0.76 | 1.78 | 0.08 | ||||||||||

| -47 | 4 1/2 | 1/16 | 4.489 | 0.030 | 0.093 | 0.003 | 114.02 | 0.76 | 1.78 | 0.08 | ||||||||||

| -48 | 4 3/4 | 1/16 | 4.739 | 0.030 | 0.093 | 0.003 | 120.37 | 0.76 | 1.78 | 0.08 | ||||||||||

| -49 | 5 | 1/16 | 4.989 | 0.093 | 0.093 | 0.003 | 126.72 | 0.94 | 1.78 | 0.08 | ||||||||||

| -50 | 5 1/4 | 1/16 | 5.239 | 0.093 | 0.093 | 0.003 | 133.07 | 0.94 | 1.78 | 0.08 | ||||||||||

| -102 | 1/16 | 3/32 | 0.041 | 0.005 | 0.103 | 0.003 | 1.24 | 0.13 | 2.62 | 0.08 | ||||||||||

| -103 | 3/32 | 3/32 | 0.093 | 0.005 | 0.103 | 0.003 | 2.06 | 0.13 | 2.62 | 0.08 | ||||||||||

| -104 | 1/8 | 3/32 | 0.112 | 0.005 | 0.103 | 0.003 | 2.84 | 0.13 | 2.62 | 0.08 | ||||||||||

| -105 | 5/32 | 3/32 | 0.143 | 0.005 | 0.103 | 0.003 | 3.63 | 0.13 | 2.62 | 0.08 | ||||||||||

| -106 | 3/16 | 3/32 | 0.174 | 0.005 | 0.103 | 0.003 | 4.42 | 0.13 | 2.62 | 0.08 | ||||||||||

| -107 | 7/32 | 3/32 | 0.206 | 0.005 | 0.103 | 0.003 | 5.23 | 0.13 | 2.62 | 0.08 | ||||||||||

| -108 | 1/4 | 3/32 | 0.237 | 0.005 | 0.103 | 0.003 | 6.02 | 0.13 | 2.62 | 0.08 | ||||||||||

| -109 | 5/16 | 3/32 | 0.299 | 0.005 | 0.103 | 0.003 | 7.59 | 0.13 | 2.62 | 0.08 | ||||||||||

| -110 | 3/8 | 3/32 | 0.362 | 0.005 | 0.103 | 0.003 | 9.19 | 0.13 | 2.62 | 0.08 | ||||||||||

| -111 | 7/16 | 3/32 | 0.424 | 0.005 | 0.103 | 0.003 | 10.77 | 0.13 | 2.62 | 0.08 | ||||||||||

| -112 | 1/2 | 3/32 | 0.487 | 0.005 | 0.103 | 0.003 | 12.37 | 0.13 | 2.62 | 0.08 | ||||||||||

| -113 | 9/16 | 3/32 | 0.549 | 0.007 | 0.103 | 0.003 | 13.94 | 0.18 | 2.62 | 0.08 | ||||||||||

| -114 | 5/8 | 3/32 | 0.612 | 0.009 | 0.103 | 0.003 | 15.54 | 0.23 | 2.62 | 0.08 | ||||||||||

| -115 | 11/16 | 3/32 | 0.124 | 0.009 | 0.103 | 0.003 | 17.12 | 0.23 | 2.62 | 0.08 | ||||||||||

| -116 | 3/4 | 3/32 | 0.737 | 0.009 | 0.103 | 0.003 | 18.72 | 0.23 | 2.62 | 0.08 | ||||||||||

| -117 | 13/16 | 3/32 | 0.799 | 0.013 | 0.103 | 0.003 | 20.29 | 0.25 | 2.62 | 0.08 | ||||||||||

| -118 | 7/8 | 3/32 | 0.862 | 0.013 | 0.103 | 0.003 | 21.89 | 0.25 | 2.62 | 0.08 | ||||||||||

| -119 | 15/16 | 3/32 | 0.924 | 0.013 | 0.103 | 0.003 | 23.47 | 0.25 | 2.62 | 0.08 | ||||||||||

| -120 | 1 | 3/32 | 0.987 | 0.013 | 0.103 | 0.003 | 25.07 | 0.25 | 2.62 | 0.08 | ||||||||||

| -121 | 1 1/16 | 3/32 | 1.049 | 0.013 | 0.103 | 0.003 | 26.64 | 0.25 | 2.62 | 0.08 | ||||||||||

| -122 | 1 1/8 | 3/32 | 1.112 | 0.013 | 0.103 | 0.003 | 28.24 | 0.25 | 2.62 | 0.08 | ||||||||||

| -123 | 1 3/16 | 3/32 | 1.174 | 0.012 | 0.103 | 0.003 | 29.82 | 0.30 | 2.62 | 0.08 | ||||||||||

| -124 | 1 1/4 | 3/32 | 1.237 | 0.012 | 0.103 | 0.003 | 31.42 | 0.30 | 2.62 | 0.08 | ||||||||||

| -125 | 1 5/16 | 3/32 | 1.299 | 0.012 | 0.103 | 0.003 | 32.99 | 0.30 | 2.62 | 0.08 | ||||||||||

| -126 | 1 3/8 | 3/32 | 1.362 | 0.012 | 0.103 | 0.003 | 34.59 | 0.30 | 2.62 | 0.08 | ||||||||||

| -127 | 1 7/16 | 3/32 | 1.424 | 0.012 | 0.103 | 0.003 | 36.17 | 0.30 | 2.62 | 0.08 | ||||||||||

| -128 | 1 1/2 | 3/32 | 1.487 | 0.012 | 0.103 | 0.003 | 37.77 | 0.30 | 2.62 | 0.08 | ||||||||||

| -129 | 1 9/16 | 3/32 | 1.549 | 0.014 | 0.103 | 0.003 | 39.34 | 0.38 | 2.62 | 0.08 | ||||||||||

| -130 | 1 5/8 | 3/32 | 1.612 | 0.014 | 0.103 | 0.003 | 40.94 | 0.38 | 2.62 | 0.08 | ||||||||||

| -131 | 1 11/16 | 3/32 | 1.674 | 0.014 | 0.103 | 0.003 | 42.52 | 0.38 | 2.62 | 0.08 | ||||||||||

| -132 | 1 3/4 | 3/32 | 1.737 | 0.014 | 0.103 | 0.003 | 44.12 | 0.38 | 2.62 | 0.08 | ||||||||||

| -133 | 1 13/16 | 3/32 | 1.799 | 0.014 | 0.103 | 0.003 | 45.69 | 0.38 | 2.62 | 0.08 | ||||||||||

| -134 | 1 7/8 | 3/32 | 1.862 | 0.014 | 0.103 | 0.003 | 47.29 | 0.38 | 2.62 | 0.08 | ||||||||||

| -135 | 1 15/16 | 3/32 | 1.925 | 0.017 | 0.103 | 0.003 | 48.90 | 0.43 | 2.62 | 0.08 | ||||||||||

| -136 | 2 | 3/32 | 1.987 | 0.017 | 0.103 | 0.003 | 50.47 | 0.43 | 2.62 | 0.08 | ||||||||||

| -137 | 2 1/16 | 3/32 | 2.050 | 0.017 | 0.103 | 0.003 | 52.07 | 0.43 | 2.62 | 0.08 | ||||||||||

| -138 | 2 1/8 | 3/32 | 2.112 | 0.017 | 0.103 | 0.003 | 53.64 | 0.43 | 2.62 | 0.08 | ||||||||||

| -139 | 2 3/16 | 3/32 | 2.175 | 0.017 | 0.103 | 0.003 | 55.25 | 0.43 | 2.62 | 0.08 | ||||||||||

| -140 | 2 1/4 | 3/32 | 2.237 | 0.017 | 0.103 | 0.003 | 56.82 | 0.43 | 2.62 | 0.08 | ||||||||||

| -141 | 2 5/16 | 3/32 | 2.300 | 0.018 | 0.103 | 0.003 | 58.42 | 0.51 | 2.62 | 0.08 | ||||||||||

| -142 | 2 3/8 | 3/32 | 2.362 | 0.018 | 0.103 | 0.003 | 59.99 | 0.51 | 2.62 | 0.08 | ||||||||||

| -143 | 2 7/16 | 3/32 | 2.425 | 0.018 | 0.103 | 0.003 | 61.60 | 0.51 | 2.62 | 0.08 | ||||||||||

| -144 | 2 1/2 | 3/32 | 2.487 | 0.018 | 0.103 | 0.003 | 63.17 | 0.51 | 2.62 | 0.08 | ||||||||||

| -145 | 2 9/16 | 3/32 | 2.550 | 0.018 | 0.103 | 0.003 | 64.77 | 0.51 | 2.62 | 0.08 | ||||||||||

| -146 | 2 5/8 | 3/32 | 2.612 | 0.018 | 0.103 | 0.003 | 66.34 | 0.51 | 2.62 | 0.08 | ||||||||||

| -147 | 2 11/16 | 3/32 | 2.675 | 0.022 | 0.103 | 0.003 | 67.95 | 0.56 | 2.62 | 0.08 | ||||||||||

| -148 | 2 3/4 | 3/32 | 2.737 | 0.022 | 0.103 | 0.003 | 69.52 | 0.56 | 2.62 | 0.08 | ||||||||||

| -149 | 2 13/16 | 3/32 | 2.800 | 0.022 | 0.103 | 0.003 | 71.12 | 0.56 | 2.62 | 0.08 | ||||||||||

| -150 | 2 7/8 | 3/32 | 2.862 | 0.022 | 0.103 | 0.003 | 72.69 | 0.56 | 2.62 | 0.08 | ||||||||||

| -151 | 3 | 3/32 | 2.987 | 0.024 | 0.103 | 0.003 | 75.87 | 0.61 | 2.62 | 0.08 | ||||||||||

| -152 | 3 1/4 | 3/32 | 3.237 | 0.024 | 0.103 | 0.003 | 82.22 | 0.61 | 2.62 | 0.08 | ||||||||||

| -153 | 3 1/2 | 3/32 | 3.487 | 0.024 | 0.103 | 0.003 | 88.57 | 0.61 | 2.62 | 0.08 | ||||||||||

| -154 | 3 3/4 | 3/32 | 3.737 | 0.028 | 0.103 | 0.003 | 94.92 | 0.71 | 2.62 | 0.08 | ||||||||||

| -155 | 4 | 3/32 | 3.987 | 0.028 | 0.103 | 0.003 | 101.27 | 0.71 | 2.62 | 0.08 | ||||||||||

| -156 | 4 1/4 | 3/32 | 4.237 | 0.030 | 0.103 | 0.003 | 107.62 | 0.76 | 2.62 | 0.08 | ||||||||||

| -157 | 4 1/2 | 3/32 | 4.487 | 0.030 | 0.103 | 0.003 | 113.97 | 0.76 | 2.62 | 0.08 | ||||||||||

| -158 | 4 3/4 | 3/32 | 4.737 | 0.030 | 0.103 | 0.003 | 120.32 | 0.76 | 2.62 | 0.08 | ||||||||||

| -159 | 5 | 3/32 | 4.987 | 0.035 | 0.103 | 0.003 | 126.67 | 0.89 | 2.62 | 0.08 | ||||||||||

| -160 | 5 1/4 | 3/32 | 5.237 | 0.035 | 0.103 | 0.003 | 133.02 | 0.89 | 2.62 | 0.08 | ||||||||||

| -161 | 5 1/2 | 3/32 | 5.487 | 0.035 | 0.103 | 0.003 | 139.37 | 0.89 | 2.62 | 0.08 | ||||||||||

| -162 | 5 3/4 | 3/32 | 5.737 | 0.035 | 0.103 | 0.003 | 145.72 | 0.89 | 2.62 | 0.08 | ||||||||||

| -163 | 6 | 3/32 | 5.987 | 0.035 | 0.103 | 0.003 | 152.07 | 0.89 | 2.62 | 0.08 | ||||||||||

| -164 | 6 1/4 | 3/32 | 6.237 | 0.041 | 0.103 | 0.003 | 158.42 | 1.02 | 2.62 | 0.08 | ||||||||||

| -165 | 6 1/2 | 3/32 | 6.487 | 0.041 | 0.103 | 0.003 | 164.77 | 1.02 | 2.62 | 0.08 | ||||||||||

| -166 | 6 3/4 | 3/32 | 6.737 | 0.041 | 0.103 | 0.003 | 171.12 | 1.02 | 2.62 | 0.08 | ||||||||||

| -167 | 7 | 3/32 | 6.987 | 0.041 | 0.103 | 0.003 | 177.47 | 1.02 | 2.62 | 0.08 | ||||||||||

| -168 | 7 1/4 | 3/32 | 7.237 | 0.041 | 0.103 | 0.003 | 183.82 | 1.14 | 2.62 | 0.08 | ||||||||||

| -169 | 7 1/2 | 3/32 | 7.487 | 0.041 | 0.103 | 0.003 | 190.17 | 1.14 | 2.62 | 0.08 | ||||||||||

| -170 | 7 3/4 | 3/32 | 7.737 | 0.041 | 0.103 | 0.003 | 196.52 | 1.14 | 2.62 | 0.08 | ||||||||||

| -171 | 8 | 3/32 | 7.987 | 0.041 | 0.103 | 0.003 | 202.87 | 1.14 | 2.62 | 0.08 | ||||||||||

| -172 | 8 1/4 | 3/32 | 8.237 | 0.041 | 0.103 | 0.003 | 209.22 | 1.27 | 2.62 | 0.08 | ||||||||||

| -173 | 8 1/2 | 3/32 | 8.487 | 0.041 | 0.103 | 0.003 | 215.57 | 1.27 | 2.62 | 0.08 | ||||||||||

| -174 | 8 3/4 | 3/32 | 8.737 | 0.041 | 0.103 | 0.003 | 221.92 | 1.27 | 2.62 | 0.08 | ||||||||||

| -175 | 9 | 3/32 | 8.987 | 0.041 | 0.103 | 0.003 | 228.27 | 1.27 | 2.62 | 0.08 | ||||||||||

| -176 | 9 1/4 | 3/32 | 9.237 | 0.093 | 0.103 | 0.003 | 234.62 | 1.40 | 2.62 | 0.08 | ||||||||||

| -177 | 9 1/2 | 3/32 | 9.487 | 0.093 | 0.103 | 0.003 | 240.97 | 1.40 | 2.62 | 0.08 | ||||||||||

| -178 | 9 3/4 | 3/32 | 9.737 | 0.093 | 0.103 | 0.003 | 247.32 | 1.40 | 2.62 | 0.08 | ||||||||||

| -201 | 3/16 | 1/8 | 0.171 | 0.005 | 0.139 | 0.004 | 4.34 | 0.13 | 3.53 | 0.10 | ||||||||||

| -202 | 1/4 | 1/8 | 0.234 | 0.005 | 0.139 | 0.004 | 5.94 | 0.13 | 3.53 | 0.10 | ||||||||||

| -203 | 5/16 | 1/8 | 0.296 | 0.005 | 0.139 | 0.004 | 7.52 | 0.13 | 3.53 | 0.10 | ||||||||||

| -204 | 3/8 | 1/8 | 0.359 | 0.005 | 0.139 | 0.004 | 9.12 | 0.13 | 3.53 | 0.10 | ||||||||||

| -205 | 7/16 | 1/8 | 0.421 | 0.005 | 0.139 | 0.004 | 10.69 | 0.13 | 3.53 | 0.10 | ||||||||||

| -206 | 1/2 | 1/8 | 0.484 | 0.005 | 0.139 | 0.004 | 12.29 | 0.13 | 3.53 | 0.10 | ||||||||||

| -207 | 9/16 | 1/8 | 0.556 | 0.007 | 0.139 | 0.004 | 13.87 | 0.18 | 3.53 | 0.10 | ||||||||||

| -208 | 5/8 | 1/8 | 0.609 | 0.009 | 0.139 | 0.004 | 15.47 | 0.23 | 3.53 | 0.10 | ||||||||||

| -209 | 11/16 | 1/8 | 0.691 | 0.009 | 0.139 | 0.004 | 17.04 | 0.23 | 3.53 | 0.10 | ||||||||||

| -210 | 3/4 | 1/8 | 0.734 | 0.013 | 0.139 | 0.004 | 18.64 | 0.25 | 3.53 | 0.10 | ||||||||||

| -211 | 13/16 | 1/8 | 0.796 | 0.013 | 0.139 | 0.004 | 20.22 | 0.25 | 3.53 | 0.10 | ||||||||||

| -212 | 7/8 | 1/8 | 0.859 | 0.013 | 0.139 | 0.004 | 21.82 | 0.25 | 3.53 | 0.10 | ||||||||||

| -213 | 15/16 | 1/8 | 0.921 | 0.013 | 0.139 | 0.004 | 23.39 | 0.25 | 3.53 | 0.10 | ||||||||||

| -214 | 1 | 1/8 | 0.984 | 0.013 | 0.139 | 0.004 | 24.99 | 0.25 | 3.53 | 0.10 | ||||||||||

| -215 | 1 1/16 | 1/8 | 1.046 | 0.013 | 0.139 | 0.004 | 26.57 | 0.25 | 3.53 | 0.10 | ||||||||||

| -216 | 1 1/8 | 1/8 | 1.109 | 0.012 | 0.139 | 0.004 | 28.17 | 0.30 | 3.53 | 0.10 | ||||||||||

| -217 | 1 3/16 | 1/8 | 1.171 | 0.012 | 0.139 | 0.004 | 29.74 | 0.30 | 3.53 | 0.10 | ||||||||||

| -218 | 1 1/4 | 1/8 | 1.234 | 0.012 | 0.139 | 0.004 | 31.34 | 0.30 | 3.53 | 0.10 | ||||||||||

| -219 | 1 5/16 | 1/8 | 1.296 | 0.012 | 0.139 | 0.004 | 32.92 | 0.30 | 3.53 | 0.10 | ||||||||||

| -220 | 1 3/8 | 1/8 | 1.359 | 0.012 | 0.139 | 0.004 | 34.52 | 0.30 | 3.53 | 0.10 | ||||||||||

| -221 | 1 7/16 | 1/8 | 1.421 | 0.012 | 0.139 | 0.004 | 36.09 | 0.30 | 3.53 | 0.10 | ||||||||||

| -222 | 1 1/2 | 1/8 | 1.484 | 0.014 | 0.139 | 0.004 | 37.69 | 0.38 | 3.53 | 0.10 | ||||||||||

| -223 | 1 5/8 | 1/8 | 1.609 | 0.014 | 0.139 | 0.004 | 40.87 | 0.38 | 3.53 | 0.10 | ||||||||||

| -224 | 1 3/4 | 1/8 | 1.734 | 0.014 | 0.139 | 0.004 | 44.04 | 0.38 | 3.53 | 0.10 | ||||||||||

| -225 | 1 7/8 | 1/8 | 1.859 | 0.018 | 0.139 | 0.004 | 47.22 | 0.46 | 3.53 | 0.10 | ||||||||||

| -226 | 2 | 1/8 | 1.984 | 0.018 | 0.139 | 0.004 | 50.39 | 0.46 | 3.53 | 0.10 | ||||||||||

| -227 | 2 1/8 | 1/8 | 2.109 | 0.018 | 0.139 | 0.004 | 53.57 | 0.46 | 3.53 | 0.10 | ||||||||||

| -228 | 2 1/4 | 1/8 | 2.234 | 0.018 | 0.139 | 0.004 | 56.74 | 0.51 | 3.53 | 0.10 | ||||||||||

| -229 | 2 3/8 | 1/8 | 2.359 | 0.018 | 0.139 | 0.004 | 59.92 | 0.51 | 3.53 | 0.10 | ||||||||||

| -230 | 2 1/2 | 1/8 | 2.484 | 0.018 | 0.139 | 0.004 | 63.09 | 0.51 | 3.53 | 0.10 | ||||||||||

| -231 | 2 5/8 | 1/8 | 2.609 | 0.018 | 0.139 | 0.004 | 66.27 | 0.51 | 3.53 | 0.10 | ||||||||||

| -232 | 2 3/4 | 1/8 | 2.734 | 0.024 | 0.139 | 0.004 | 69.44 | 0.61 | 3.53 | 0.10 | ||||||||||

| -233 | 2 7/8 | 1/8 | 2.859 | 0.024 | 0.139 | 0.004 | 72.62 | 0.61 | 3.53 | 0.10 | ||||||||||

| -234 | 3 | 1/8 | 2.984 | 0.024 | 0.139 | 0.004 | 75.79 | 0.61 | 3.53 | 0.10 | ||||||||||

| -235 | 3 1/8 | 1/8 | 3.109 | 0.024 | 0.139 | 0.004 | 78.97 | 0.61 | 3.53 | 0.10 | ||||||||||

| -236 | 3 1/4 | 1/8 | 3.234 | 0.024 | 0.139 | 0.004 | 82.14 | 0.61 | 3.53 | 0.10 | ||||||||||

| -237 | 3 3/8 | 1/8 | 3.359 | 0.024 | 0.139 | 0.004 | 85.32 | 0.61 | 3.53 | 0.10 | ||||||||||

| -238 | 3 1/2 | 1/8 | 3.484 | 0.024 | 0.139 | 0.004 | 88.49 | 0.61 | 3.53 | 0.10 | ||||||||||

| -239 | 3 5/8 | 1/8 | 3.609 | 0.028 | 0.139 | 0.004 | 91.67 | 0.71 | 3.53 | 0.10 | ||||||||||

| -240 | 3 3/4 | 1/8 | 3.734 | 0.028 | 0.139 | 0.004 | 94.84 | 0.71 | 3.53 | 0.10 | ||||||||||

| -241 | 3 7/8 | 1/8 | 3.859 | 0.028 | 0.139 | 0.004 | 98.02 | 0.71 | 3.53 | 0.10 | ||||||||||

| -242 | 4 | 1/8 | 3.984 | 0.028 | 0.139 | 0.004 | 101.19 | 0.71 | 3.53 | 0.10 | ||||||||||

| -243 | 4 1/8 | 1/8 | 4.109 | 0.028 | 0.139 | 0.004 | 104.37 | 0.71 | 3.53 | 0.10 | ||||||||||

| -244 | 4 1/4 | 1/8 | 4.234 | 0.030 | 0.139 | 0.004 | 107.54 | 0.76 | 3.53 | 0.10 | ||||||||||

| -245 | 4 3/8 | 1/8 | 4.359 | 0.030 | 0.139 | 0.004 | 110.72 | 0.76 | 3.53 | 0.10 | ||||||||||

| -246 | 4 1/2 | 1/8 | 4.484 | 0.030 | 0.139 | 0.004 | 113.89 | 0.76 | 3.53 | 0.10 | ||||||||||

| -247 | 4 5/8 | 1/8 | 4.609 | 0.030 | 0.139 | 0.004 | 117.07 | 0.76 | 3.53 | 0.10 | ||||||||||

| -248 | 4 3/4 | 1/8 | 4.734 | 0.030 | 0.139 | 0.004 | 120.24 | 0.76 | 3.53 | 0.10 | ||||||||||

| -249 | 4 7/8 | 1/8 | 4.859 | 0.035 | 0.139 | 0.004 | 123.42 | 0.89 | 3.53 | 0.10 | ||||||||||

| -250 | 5 | 1/8 | 4.984 | 0.035 | 0.139 | 0.004 | 126.59 | 0.89 | 3.53 | 0.10 | ||||||||||

| -251 | 5 1/8 | 1/8 | 5.109 | 0.035 | 0.139 | 0.004 | 129.77 | 0.89 | 3.53 | 0.10 | ||||||||||

| -252 | 5 1/4 | 1/8 | 5.234 | 0.035 | 0.139 | 0.004 | 132.94 | 0.89 | 3.53 | 0.10 | ||||||||||

| -253 | 5 3/8 | 1/8 | 5.359 | 0.035 | 0.139 | 0.004 | 136.12 | 0.89 | 3.53 | 0.10 | ||||||||||

| -254 | 5 1/2 | 1/8 | 5.484 | 0.035 | 0.139 | 0.004 | 139.29 | 0.89 | 3.53 | 0.10 | ||||||||||

| -255 | 5 5/8 | 1/8 | 5.609 | 0.035 | 0.139 | 0.004 | 142.47 | 0.89 | 3.53 | 0.10 | ||||||||||

| -256 | 5 3/4 | 1/8 | 5.734 | 0.035 | 0.139 | 0.004 | 145.64 | 0.89 | 3.53 | 0.10 | ||||||||||

| -257 | 5 7/8 | 1/8 | 5.859 | 0.035 | 0.139 | 0.004 | 148.82 | 0.89 | 3.53 | 0.10 | ||||||||||

| -258 | 6 | 1/8 | 5.984 | 0.035 | 0.139 | 0.004 | 151.99 | 0.89 | 3.53 | 0.10 | ||||||||||

| -259 | 6 1/4 | 1/8 | 6.234 | 0.041 | 0.139 | 0.004 | 158.34 | 1.02 | 3.53 | 0.10 | ||||||||||

| -260 | 6 1/2 | 1/8 | 6.484 | 0.041 | 0.139 | 0.004 | 164.69 | 1.02 | 3.53 | 0.10 | ||||||||||

| -261 | 6 3/4 | 1/8 | 6.734 | 0.041 | 0.139 | 0.004 | 171.04 | 1.02 | 3.53 | 0.10 | ||||||||||

| -262 | 7 | 1/8 | 6.984 | 0.041 | 0.139 | 0.004 | 177.39 | 1.02 | 3.53 | 0.10 | ||||||||||

| -263 | 7 1/4 | 1/8 | 7.234 | 0.041 | 0.139 | 0.004 | 183.74 | 1.14 | 3.53 | 0.10 | ||||||||||

| -264 | 7 1/2 | 1/8 | 7.484 | 0.041 | 0.139 | 0.004 | 190.09 | 1.14 | 3.53 | 0.10 | ||||||||||

| -265 | 7 3/4 | 1/8 | 7.734 | 0.041 | 0.139 | 0.004 | 196.44 | 1.14 | 3.53 | 0.10 | ||||||||||

| -266 | 8 | 1/8 | 7.984 | 0.041 | 0.139 | 0.004 | 202.79 | 1.14 | 3.53 | 0.10 | ||||||||||

| -267 | 8 1/4 | 1/8 | 8.234 | 0.041 | 0.139 | 0.004 | 209.14 | 1.27 | 3.53 | 0.10 | ||||||||||

| -268 | 8 1/2 | 1/8 | 8.484 | 0.041 | 0.139 | 0.004 | 215.49 | 1.27 | 3.53 | 0.10 | ||||||||||

| -269 | 8 3/4 | 1/8 | 8.734 | 0.041 | 0.139 | 0.004 | 221.84 | 1.27 | 3.53 | 0.10 | ||||||||||

| -270 | 9 | 1/8 | 8.984 | 0.041 | 0.139 | 0.004 | 228.19 | 1.27 | 3.53 | 0.10 | ||||||||||

| -271 | 9 1/4 | 1/8 | 9.234 | 0.093 | 0.139 | 0.004 | 234.54 | 1.40 | 3.53 | 0.10 | ||||||||||

| -272 | 9 1/2 | 1/8 | 9.484 | 0.093 | 0.139 | 0.004 | 240.89 | 1.40 | 3.53 | 0.10 | ||||||||||

| -273 | 9 3/4 | 1/8 | 9.734 | 0.093 | 0.139 | 0.004 | 247.24 | 1.40 | 3.53 | 0.10 | ||||||||||

| -274 | 10 | 1/8 | 9.984 | 0.093 | 0.139 | 0.004 | 253.59 | 1.40 | 3.53 | 0.10 | ||||||||||

| -275 | 10 1/2 | 1/8 | 10.484 | 0.093 | 0.139 | 0.004 | 266.29 | 1.40 | 3.53 | 0.10 | ||||||||||

| -276 | 11 | 1/8 | 10.984 | 0.093 | 0.139 | 0.004 | 278.99 | 1.65 | 3.53 | 0.10 | ||||||||||

| -277 | 11 1/2 | 1/8 | 11.484 | 0.093 | 0.139 | 0.004 | 291.69 | 1.65 | 3.53 | 0.10 | ||||||||||

| -278 | 12 | 1/8 | 11.984 | 0.093 | 0.139 | 0.004 | 304.39 | 1.65 | 3.53 | 0.10 | ||||||||||

| -279 | 13 | 1/8 | 12.984 | 0.093 | 0.139 | 0.004 | 329.79 | 1.65 | 3.53 | 0.10 | ||||||||||

| -280 | 14 | 1/8 | 13.984 | 0.093 | 0.139 | 0.004 | 355.19 | 1.65 | 3.53 | 0.10 | ||||||||||

| -281 | 15 | 1/8 | 14.984 | 0.093 | 0.139 | 0.004 | 380.59 | 1.65 | 3.53 | 0.10 | ||||||||||

| -282 | 16 | 1/8 | 15.955 | 0.093 | 0.139 | 0.004 | 405.26 | 1.91 | 3.53 | 0.10 | ||||||||||

| -283 | 17 | 1/8 | 16.955 | 0.093 | 0.139 | 0.004 | 430.66 | 2.03 | 3.53 | 0.10 | ||||||||||

| -284 | 18 | 1/8 | 17.955 | 0.093 | 0.139 | 0.004 | 456.06 | 2.16 | 3.53 | 0.10 | ||||||||||

| -309 | 7/16 | 3/16 | 0.412 | 0.005 | 0.210 | 0.005 | 10.46 | 0.13 | 5.33 | 0.13 | ||||||||||

| -310 | 1/2 | 3/16 | 0.475 | 0.005 | 0.210 | 0.005 | 12.07 | 0.13 | 5.33 | 0.13 | ||||||||||

| -311 | 9/16 | 3/16 | 0.537 | 0.007 | 0.210 | 0.005 | 13.64 | 0.18 | 5.33 | 0.13 | ||||||||||

| -312 | 5/8 | 3/16 | 0.600 | 0.009 | 0.210 | 0.005 | 15.24 | 0.23 | 5.33 | 0.13 | ||||||||||

| -313 | 11/16 | 3/16 | 0.662 | 0.009 | 0.210 | 0.005 | 16.81 | 0.23 | 5.33 | 0.13 | ||||||||||

| -314 | 3/4 | 3/16 | 0.725 | 0.013 | 0.210 | 0.005 | 18.42 | 0.25 | 5.33 | 0.13 | ||||||||||

| -315 | 13/16 | 3/16 | 0.093 | 0.013 | 0.210 | 0.005 | 19.99 | 0.25 | 5.33 | 0.13 | ||||||||||

| -316 | 7/8 | 3/16 | 0.850 | 0.013 | 0.210 | 0.005 | 21.59 | 0.25 | 5.33 | 0.13 | ||||||||||

| -317 | 15/16 | 3/16 | 0.912 | 0.013 | 0.210 | 0.005 | 23.16 | 0.25 | 5.33 | 0.13 | ||||||||||

| -318 | 1 | 3/16 | 0.975 | 0.013 | 0.210 | 0.005 | 24.77 | 0.25 | 5.33 | 0.13 | ||||||||||

| -319 | 1 1/16 | 3/16 | 1.037 | 0.013 | 0.210 | 0.005 | 26.34 | 0.25 | 5.33 | 0.13 | ||||||||||

| -320 | 1 1/8 | 3/16 | 1.100 | 0.012 | 0.210 | 0.005 | 27.94 | 0.30 | 5.33 | 0.13 | ||||||||||

| -321 | 1 3/16 | 3/16 | 1.162 | 0.012 | 0.210 | 0.005 | 29.51 | 0.30 | 5.33 | 0.13 | ||||||||||

| -322 | 1 1/4 | 3/16 | 1.225 | 0.012 | 0.210 | 0.005 | 31.12 | 0.30 | 5.33 | 0.13 | ||||||||||

| -323 | 1 5/16 | 3/16 | 1.287 | 0.012 | 0.210 | 0.005 | 32.69 | 0.30 | 5.33 | 0.13 | ||||||||||

| -324 | 1 3/8 | 3/16 | 1.350 | 0.012 | 0.210 | 0.005 | 34.29 | 0.30 | 5.33 | 0.13 | ||||||||||

| -325 | 1 1/2 | 3/16 | 1.475 | 0.014 | 0.210 | 0.005 | 37.47 | 0.38 | 5.33 | 0.13 | ||||||||||

| -326 | 1 5/8 | 3/16 | 1.600 | 0.014 | 0.210 | 0.005 | 40.64 | 0.38 | 5.33 | 0.13 | ||||||||||

| -327 | 1 3/4 | 3/16 | 1.725 | 0.014 | 0.210 | 0.005 | 43.82 | 0.38 | 5.33 | 0.13 | ||||||||||

| -328 | 1 7/8 | 3/16 | 1.850 | 0.014 | 0.210 | 0.005 | 46.99 | 0.38 | 5.33 | 0.13 | ||||||||||

| -329 | 2 | 3/16 | 1.975 | 0.018 | 0.210 | 0.005 | 50.17 | 0.46 | 5.33 | 0.13 | ||||||||||

| -330 | 2 1/8 | 3/16 | 2.100 | 0.018 | 0.210 | 0.005 | 53.34 | 0.46 | 5.33 | 0.13 | ||||||||||

| -331 | 2 1/4 | 3/16 | 2.225 | 0.018 | 0.210 | 0.005 | 56.52 | 0.46 | 5.33 | 0.13 | ||||||||||

| -332 | 2 3/8 | 3/16 | 2.350 | 0.018 | 0.210 | 0.005 | 59.69 | 0.46 | 5.33 | 0.13 | ||||||||||

| -333 | 2 1/2 | 3/16 | 2.475 | 0.018 | 0.210 | 0.005 | 62.87 | 0.51 | 5.33 | 0.13 | ||||||||||

| -334 | 2 5/8 | 3/16 | 2.600 | 0.018 | 0.210 | 0.005 | 66.04 | 0.51 | 5.33 | 0.13 | ||||||||||

| -335 | 2 3/4 | 3/16 | 2.725 | 0.018 | 0.210 | 0.005 | 69.22 | 0.51 | 5.33 | 0.13 | ||||||||||

| -336 | 2 7/8 | 3/16 | 2.850 | 0.018 | 0.210 | 0.005 | 72.39 | 0.51 | 5.33 | 0.13 | ||||||||||

| -337 | 3 | 3/16 | 2.975 | 0.024 | 0.210 | 0.005 | 75.57 | 0.61 | 5.33 | 0.13 | ||||||||||

| -338 | 3 1/8 | 3/16 | 3.100 | 0.024 | 0.210 | 0.005 | 78.74 | 0.61 | 5.33 | 0.13 | ||||||||||

| -339 | 3 1/4 | 3/16 | 3.225 | 0.024 | 0.210 | 0.005 | 81.92 | 0.61 | 5.33 | 0.13 | ||||||||||

| -340 | 3 3/8 | 3/16 | 3.350 | 0.024 | 0.210 | 0.005 | 85.09 | 0.61 | 5.33 | 0.13 | ||||||||||

| -341 | 3 1/2 | 3/16 | 3.475 | 0.024 | 0.210 | 0.005 | 88.27 | 0.61 | 5.33 | 0.13 | ||||||||||

| -342 | 3 5/8 | 3/16 | 3.600 | 0.028 | 0.210 | 0.005 | 91.44 | 0.71 | 5.33 | 0.13 | ||||||||||

| -343 | 3 3/4 | 3/16 | 3.725 | 0.028 | 0.210 | 0.005 | 94.62 | 0.71 | 5.33 | 0.13 | ||||||||||

| -344 | 3 7/8 | 3/16 | 3.850 | 0.028 | 0.210 | 0.005 | 97.79 | 0.71 | 5.33 | 0.13 | ||||||||||

| -345 | 4 | 3/16 | 3.975 | 0.028 | 0.210 | 0.005 | 100.97 | 0.71 | 5.33 | 0.13 | ||||||||||

| -346 | 4 1/8 | 3/16 | 4.100 | 0.028 | 0.210 | 0.005 | 104.14 | 0.71 | 5.33 | 0.13 | ||||||||||

| -347 | 4 1/4 | 3/16 | 4.225 | 0.030 | 0.210 | 0.005 | 107.32 | 0.76 | 5.33 | 0.13 | ||||||||||

| -348 | 4 3/8 | 3/16 | 4.350 | 0.030 | 0.210 | 0.005 | 110.49 | 0.76 | 5.33 | 0.13 | ||||||||||

| -349 | 4 1/2 | 3/16 | 4.475 | 0.030 | 0.210 | 0.005 | 113.67 | 0.76 | 5.33 | 0.13 | ||||||||||

| -350 | 4 5/8 | 3/16 | 4.600 | 0.030 | 0.210 | 0.005 | 116.84 | 0.76 | 5.33 | 0.13 | ||||||||||

| -351 | 4 3/4 | 3/16 | 4.725 | 0.030 | 0.210 | 0.005 | 120.02 | 0.76 | 5.33 | 0.13 | ||||||||||

| -352 | 4 7/8 | 3/16 | 4.850 | 0.030 | 0.210 | 0.005 | 123.19 | 0.76 | 5.33 | 0.13 | ||||||||||

| -353 | 5 | 3/16 | 4.975 | 0.093 | 0.210 | 0.005 | 126.37 | 0.94 | 5.33 | 0.13 | ||||||||||

| -354 | 5 1/8 | 3/16 | 5.100 | 0.093 | 0.210 | 0.005 | 129.54 | 0.94 | 5.33 | 0.13 | ||||||||||

| -355 | 5 1/4 | 3/16 | 5.225 | 0.093 | 0.210 | 0.005 | 132.72 | 0.94 | 5.33 | 0.13 | ||||||||||

| -356 | 5 3/8 | 3/16 | 5.350 | 0.093 | 0.210 | 0.005 | 135.89 | 0.94 | 5.33 | 0.13 | ||||||||||

| -357 | 5 1/2 | 3/16 | 5.475 | 0.093 | 0.210 | 0.005 | 139.07 | 0.94 | 5.33 | 0.13 | ||||||||||

| -358 | 5 5/8 | 3/16 | 5.600 | 0.093 | 0.210 | 0.005 | 142.24 | 0.94 | 5.33 | 0.13 | ||||||||||

| -359 | 5 3/4 | 3/16 | 5.725 | 0.093 | 0.210 | 0.005 | 145.42 | 0.94 | 5.33 | 0.13 | ||||||||||

| -360 | 5 7/8 | 3/16 | 5.850 | 0.093 | 0.210 | 0.005 | 148.59 | 0.94 | 5.33 | 0.13 | ||||||||||

| -361 | 6 | 3/16 | 5.975 | 0.093 | 0.210 | 0.005 | 151.77 | 0.94 | 5.33 | 0.13 | ||||||||||

| -362 | 6 1/4 | 3/16 | 6.225 | 0.041 | 0.210 | 0.005 | 158.12 | 1.02 | 5.33 | 0.13 | ||||||||||

| -363 | 6 1/2 | 3/16 | 6.475 | 0.041 | 0.210 | 0.005 | 164.47 | 1.02 | 5.33 | 0.13 | ||||||||||

| -364 | 6 3/4 | 3/16 | 6.725 | 0.041 | 0.210 | 0.005 | 170.82 | 1.02 | 5.33 | 0.13 | ||||||||||

| -365 | 7 | 3/16 | 6.975 | 0.041 | 0.210 | 0.005 | 177.17 | 1.02 | 5.33 | 0.13 | ||||||||||

| -366 | 7 1/4 | 3/16 | 7.225 | 0.041 | 0.210 | 0.005 | 183.52 | 1.14 | 5.33 | 0.13 | ||||||||||

| -367 | 7 1/2 | 3/16 | 7.475 | 0.041 | 0.210 | 0.005 | 189.87 | 1.14 | 5.33 | 0.13 | ||||||||||

| -368 | 7 3/4 | 3/16 | 7.725 | 0.041 | 0.210 | 0.005 | 196.22 | 1.14 | 5.33 | 0.13 | ||||||||||

| -369 | 8 | 3/16 | 7.975 | 0.041 | 0.210 | 0.005 | 202.57 | 1.14 | 5.33 | 0.13 | ||||||||||

| -370 | 8 1/4 | 3/16 | 8.225 | 0.041 | 0.210 | 0.005 | 208.92 | 1.27 | 5.33 | 0.13 | ||||||||||

| -371 | 8 1/2 | 3/16 | 8.475 | 0.041 | 0.210 | 0.005 | 215.27 | 1.27 | 5.33 | 0.13 | ||||||||||

| -372 | 8 3/4 | 3/16 | 8.725 | 0.041 | 0.210 | 0.005 | 221.62 | 1.27 | 5.33 | 0.13 | ||||||||||

| -373 | 9 | 3/16 | 8.975 | 0.041 | 0.210 | 0.005 | 227.97 | 1.27 | 5.33 | 0.13 | ||||||||||

| -374 | 9 1/4 | 3/16 | 9.225 | 0.093 | 0.210 | 0.005 | 234.32 | 1.40 | 5.33 | 0.13 | ||||||||||

| -375 | 9 1/2 | 3/16 | 9.475 | 0.093 | 0.210 | 0.005 | 240.67 | 1.40 | 5.33 | 0.13 | ||||||||||

| -376 | 9 3/4 | 3/16 | 9.725 | 0.093 | 0.210 | 0.005 | 247.02 | 1.40 | 5.33 | 0.13 | ||||||||||

| -377 | 10 | 3/16 | 9.975 | 0.093 | 0.210 | 0.005 | 253.37 | 1.40 | 5.33 | 0.13 | ||||||||||

| -378 | 10 1/2 | 3/16 | 10.475 | 0.093 | 0.210 | 0.005 | 266.07 | 1.52 | 5.33 | 0.13 | ||||||||||

| -379 | 11 | 3/16 | 10.975 | 0.093 | 0.210 | 0.005 | 278.77 | 1.52 | 5.33 | 0.13 | ||||||||||

| -380 | 11 1/2 | 3/16 | 11.475 | 0.093 | 0.210 | 0.005 | 291.47 | 1.65 | 5.33 | 0.13 | ||||||||||

| -381 | 12 | 3/16 | 11.975 | 0.093 | 0.210 | 0.005 | 304.17 | 1.65 | 5.33 | 0.13 | ||||||||||

| -382 | 13 | 3/16 | 12.975 | 0.093 | 0.210 | 0.005 | 329.57 | 1.65 | 5.33 | 0.13 | ||||||||||

| -383 | 14 | 3/16 | 13.975 | 0.093 | 0.210 | 0.005 | 354.97 | 1.78 | 5.33 | 0.13 | ||||||||||

| -384 | 15 | 3/16 | 14.975 | 0.093 | 0.210 | 0.005 | 380.37 | 1.78 | 5.33 | 0.13 | ||||||||||

| -385 | 16 | 3/16 | 15.955 | 0.093 | 0.210 | 0.005 | 405.26 | 1.91 | 5.33 | 0.13 | ||||||||||

| -386 | 17 | 3/16 | 16.955 | 0.093 | 0.210 | 0.005 | 430.66 | 2.03 | 5.33 | 0.13 | ||||||||||

| -387 | 18 | 3/16 | 17.955 | 0.093 | 0.210 | 0.005 | 456.06 | 2.16 | 5.33 | 0.13 | ||||||||||

| -388 | 19 | 3/16 | 18.955 | 0.093 | 0.210 | 0.005 | 481.45 | 2.29 | 5.33 | 0.13 | ||||||||||

| -389 | 20 | 3/16 | 19.955 | 0.093 | 0.210 | 0.005 | 506.85 | 2.41 | 5.33 | 0.13 | ||||||||||

| -390 | 21 | 3/16 | 20.955 | 0.093 | 0.210 | 0.005 | 532.25 | 2.41 | 5.33 | 0.13 | ||||||||||

| -391 | 22 | 3/16 | 21.955 | 0.100 | 0.210 | 0.005 | 557.65 | 2.54 | 5.33 | 0.13 | ||||||||||

| -392 | 23 | 3/16 | 22.940 | 0.105 | 0.210 | 0.005 | 582.68 | 2.67 | 5.33 | 0.13 | ||||||||||

| -393 | 24 | 3/16 | 23.940 | 0.110 | 0.210 | 0.005 | 608.08 | 2.79 | 5.33 | 0.13 | ||||||||||

| -394 | 25 | 3/16 | 24.940 | 0.115 | 0.210 | 0.005 | 633.48 | 2.92 | 5.33 | 0.13 | ||||||||||

| -395 | 26 | 3/16 | 25.940 | 0.120 | 0.210 | 0.005 | 658.88 | 3.05 | 5.33 | 0.13 | ||||||||||

| -425 | 4 1/2 | 1/4 | 4.475 | 0.093 | 0.275 | 0.006 | 113.67 | 0.84 | 6.99 | 0.15 | ||||||||||

| -426 | 4 5/8 | 1/4 | 4.600 | 0.093 | 0.275 | 0.006 | 116.84 | 0.84 | 6.99 | 0.15 | ||||||||||

| -427 | 4 3/4 | 1/4 | 4.725 | 0.093 | 0.275 | 0.006 | 120.02 | 0.84 | 6.99 | 0.15 | ||||||||||

| -428 | 4 7/8 | 1/4 | 4.850 | 0.093 | 0.275 | 0.006 | 123.19 | 0.84 | 6.99 | 0.15 | ||||||||||

| -429 | 5 | 1/4 | 4.975 | 0.093 | 0.275 | 0.006 | 126.37 | 0.94 | 6.99 | 0.15 | ||||||||||

| -430 | 5 1/8 | 1/4 | 5.100 | 0.093 | 0.275 | 0.006 | 129.54 | 0.94 | 6.99 | 0.15 | ||||||||||

| -431 | 5 1/4 | 1/4 | 5.225 | 0.093 | 0.275 | 0.006 | 132.72 | 0.94 | 6.99 | 0.15 | ||||||||||

| -432 | 5 3/8 | 1/4 | 5.350 | 0.093 | 0.275 | 0.006 | 135.89 | 0.94 | 6.99 | 0.15 | ||||||||||

| -433 | 5 1/2 | 1/4 | 5.475 | 0.093 | 0.275 | 0.006 | 139.07 | 0.94 | 6.99 | 0.15 | ||||||||||

| -434 | 5 5/8 | 1/4 | 5.600 | 0.093 | 0.275 | 0.006 | 142.24 | 0.94 | 6.99 | 0.15 | ||||||||||

| -435 | 5 3/4 | 1/4 | 5.725 | 0.093 | 0.275 | 0.006 | 145.42 | 0.94 | 6.99 | 0.15 | ||||||||||

| -436 | 5 7/8 | 1/4 | 5.850 | 0.093 | 0.275 | 0.006 | 148.59 | 0.94 | 6.99 | 0.15 | ||||||||||

| -437 | 6 | 1/4 | 5.975 | 0.093 | 0.275 | 0.006 | 151.77 | 0.94 | 6.99 | 0.15 | ||||||||||

| -438 | 6 1/4 | 1/4 | 6.225 | 0.041 | 0.275 | 0.006 | 158.12 | 1.02 | 6.99 | 0.15 | ||||||||||

| -439 | 6 1/2 | 1/4 | 6.475 | 0.041 | 0.275 | 0.006 | 164.47 | 1.02 | 6.99 | 0.15 | ||||||||||

| -440 | 6 3/4 | 1/4 | 6.725 | 0.041 | 0.275 | 0.006 | 170.82 | 1.02 | 6.99 | 0.15 | ||||||||||

| -441 | 7 | 1/4 | 6.975 | 0.041 | 0.275 | 0.006 | 177.17 | 1.02 | 6.99 | 0.15 | ||||||||||

| -442 | 7 1/4 | 1/4 | 7.225 | 0.041 | 0.275 | 0.006 | 183.52 | 1.14 | 6.99 | 0.15 | ||||||||||

| -443 | 7 1/2 | 1/4 | 7.475 | 0.041 | 0.275 | 0.006 | 189.87 | 1.14 | 6.99 | 0.15 | ||||||||||

| -444 | 7 3/4 | 1/4 | 7.725 | 0.041 | 0.275 | 0.006 | 196.22 | 1.14 | 6.99 | 0.15 | ||||||||||

| -445 | 8 | 1/4 | 7.975 | 0.041 | 0.275 | 0.006 | 202.57 | 1.14 | 6.99 | 0.15 | ||||||||||

| -446 | 8 1/2 | 1/4 | 8.475 | 0.093 | 0.275 | 0.006 | 215.27 | 1.40 | 6.99 | 0.15 | ||||||||||

| -447 | 9 | 1/4 | 8.975 | 0.093 | 0.275 | 0.006 | 227.97 | 1.40 | 6.99 | 0.15 | ||||||||||

| -448 | 9 1/2 | 1/4 | 9.475 | 0.093 | 0.275 | 0.006 | 240.67 | 1.40 | 6.99 | 0.15 | ||||||||||

| -449 | 10 | 1/4 | 9.975 | 0.093 | 0.275 | 0.006 | 253.37 | 1.40 | 6.99 | 0.15 | ||||||||||

| -450 | 10 1/2 | 1/4 | 10.475 | 0.093 | 0.275 | 0.006 | 266.07 | 1.52 | 6.99 | 0.15 | ||||||||||

| -451 | 11 | 1/4 | 10.975 | 0.093 | 0.275 | 0.006 | 278.77 | 1.52 | 6.99 | 0.15 | ||||||||||

| -452 | 11 1/2 | 1/4 | 11.475 | 0.093 | 0.275 | 0.006 | 291.47 | 1.52 | 6.99 | 0.15 | ||||||||||

| -453 | 12 | 1/4 | 11.975 | 0.093 | 0.275 | 0.006 | 304.17 | 1.52 | 6.99 | 0.15 | ||||||||||

| -454 | 12 1/2 | 1/4 | 12.475 | 0.093 | 0.275 | 0.006 | 316.87 | 1.52 | 6.99 | 0.15 | ||||||||||

| -455 | 13 | 1/4 | 12.975 | 0.093 | 0.275 | 0.006 | 329.57 | 1.52 | 6.99 | 0.15 | ||||||||||

| -456 | 13 1/2 | 1/4 | 13.475 | 0.093 | 0.275 | 0.006 | 342.27 | 1.78 | 6.99 | 0.15 | ||||||||||

| -457 | 14 | 1/4 | 13.975 | 0.093 | 0.275 | 0.006 | 354.97 | 1.78 | 6.99 | 0.15 | ||||||||||

| -458 | 14 1/2 | 1/4 | 14.475 | 0.093 | 0.275 | 0.006 | 367.67 | 1.78 | 6.99 | 0.15 | ||||||||||

| -459 | 15 | 1/4 | 14.975 | 0.093 | 0.275 | 0.006 | 380.37 | 1.78 | 6.99 | 0.15 | ||||||||||

| -460 | 15 1/2 | 1/4 | 15.475 | 0.093 | 0.275 | 0.006 | 393.07 | 1.78 | 6.99 | 0.15 | ||||||||||

| -461 | 16 | 1/4 | 15.955 | 0.093 | 0.275 | 0.006 | 405.26 | 1.91 | 6.99 | 0.15 | ||||||||||

| -462 | 16 1/2 | 1/4 | 16.455 | 0.093 | 0.275 | 0.006 | 417.96 | 1.91 | 6.99 | 0.15 | ||||||||||

| -463 | 17 | 1/4 | 16.955 | 0.093 | 0.275 | 0.006 | 430.66 | 2.03 | 6.99 | 0.15 | ||||||||||

| -464 | 17a | 1/4 | 17.455 | 0.093 | 0.275 | 0.006 | 443.36 | 2.16 | 6.99 | 0.15 | ||||||||||

| -465 | 18 | 1/4 | 17.955 | 0.093 | 0.275 | 0.006 | 456.06 | 2.16 | 6.99 | 0.15 | ||||||||||

| -466 | 18 1/2 | 1/4 | 18.455 | 0.093 | 0.275 | 0.006 | 468.76 | 2.16 | 6.99 | 0.15 | ||||||||||

| -467 | 19 | 1/4 | 18.955 | 0.093 | 0.275 | 0.006 | 481.46 | 2.29 | 6.99 | 0.15 | ||||||||||

| -468 | 19 1/2 | 1/4 | 19.455 | 0.093 | 0.275 | 0.006 | 494.16 | 2.29 | 6.99 | 0.15 | ||||||||||

| -469 | 20 | 1/4 | 19.955 | 0.093 | 0.275 | 0.006 | 506.86 | 2.41 | 6.99 | 0.15 | ||||||||||

| -470 | 21 | 1/4 | 20.955 | 0.093 | 0.275 | 0.006 | 532.26 | 2.41 | 6.99 | 0.15 | ||||||||||

| -471 | 22 | 1/4 | 21.955 | 0.100 | 0.275 | 0.006 | 557.66 | 2.54 | 6.99 | 0.15 | ||||||||||

| -472 | 23 | 1/4 | 22.940 | 0.105 | 0.275 | 0.006 | 582.68 | 2.67 | 6.99 | 0.15 | ||||||||||

| -473 | 24 | 1/4 | 23.940 | 0.110 | 0.275 | 0.006 | 608.08 | 2.79 | 6.99 | 0.15 | ||||||||||

| -474 | 25 | 1/4 | 24.940 | 0.115 | 0.275 | 0.006 | 633.48 | 2.92 | 6.99 | 0.15 | ||||||||||

| -475 | 26 | 1/4 | 25.940 | 0.120 | 0.275 | 0.006 | 658.88 | 3.05 | 6.99 | 0.15 | ||||||||||

| AS568 MENSURA | Nominal ID | Id est in pollices mensurae | ±ID | Mensurae CS in pollices | ±CS | Mensurae ID in mm | ±ID | Mensurae CS in mm | ± C/S | |||||||||||

| -901 | 3/32 | 0.185 | 0.005 | 0.093 | 0.003 | 4.70 | 0.13 | 1.42 | 0.08 | |||||||||||

| -902 | 1/8 | 0.239 | 0.005 | 0.093 | 0.003 | 6.07 | 0.13 | 1.63 | 0.08 | |||||||||||

| -903 | 3/16 | 0.301 | 0.005 | 0.093 | 0.003 | 7.65 | 0.13 | 1.63 | 0.08 | |||||||||||

| -904 | 1/4 | 0.351 | 0.005 | 0.072 | 0.003 | 8.92 | 0.13 | 1.83 | 0.08 | |||||||||||

| -905 | 5/16 | 0.414 | 0.005 | 0.072 | 0.003 | 10.52 | 0.13 | 1.83 | 0.08 | |||||||||||

| -906 | 3/8 | 0.468 | 0.005 | 0.078 | 0.003 | 11.89 | 0.13 | 1.98 | 0.08 | |||||||||||

| -907 | 7/16 | 0.530 | 0.007 | 0.093 | 0.003 | 13.46 | 0.18 | 2.08 | 0.08 | |||||||||||

| -908 | 1/2 | 0.644 | 0.009 | 0.093 | 0.003 | 16.36 | 0.23 | 2.21 | 0.08 | |||||||||||

| -909 | 9/16 | 0.706 | 0.009 | 0.097 | 0.003 | 17.93 | 0.23 | 2.46 | 0.08 | |||||||||||

| -910 | 5/8 | 0.755 | 0.009 | 0.097 | 0.003 | 19.18 | 0.23 | 2.46 | 0.08 | |||||||||||

| -911 | 11/16 | 0.863 | 0.009 | 0.116 | 0.004 | 21.92 | 0.23 | 2.95 | 0.10 | |||||||||||

| -912 | 3/4 | 0.924 | 0.009 | 0.116 | 0.004 | 23.47 | 0.23 | 2.95 | 0.10 | |||||||||||

| -913 | 13/16 | 0.986 | 0.013 | 0.116 | 0.004 | 25.04 | 0.25 | 2.95 | 0.10 | |||||||||||

| -914 | 7/8 | 1.047 | 0.013 | 0.116 | 0.004 | 26.59 | 0.25 | 2.95 | 0.10 | |||||||||||

| -916 | 1 | 1.171 | 0.013 | 0.116 | 0.004 | 29.74 | 0.25 | 2.95 | 0.10 | |||||||||||

| -918 | 1 1/8 | 1.355 | 0.012 | 0.116 | 0.004 | 34.42 | 0.30 | 2.95 | 0.10 | |||||||||||

| -920 | 1 1/4 | 1.475 | 0.014 | 0.118 | 0.004 | 37.47 | 0.36 | 3.00 | 0.10 | |||||||||||

| -924 | 1 1/2 | 1.720 | 0.014 | 0.118 | 0.004 | 43.69 | 0.36 | 3.00 | 0.10 | |||||||||||

| -928 | 1 3/4 | 2.090 | 0.018 | 0.118 | 0.004 | 53.09 | 0.46 | 3.00 | 0.10 | |||||||||||

| -932 | 2 | 2.337 | 0.018 | 0.118 | 0.004 | 59.36 | 0.46 | 3.00 | 0.10 | |||||||||||

Secundo -Compression rate et extendens quantum adorings

O-anulus sigillum typicum est extructum.Compressionis ratio et extensio moles crucis-sectionalis diametri O-anuli sunt principalia contenta consilio signandi, quae magnae sunt significationis ad signationem vitae perficiendi et serviendi.Bonus effectus signandi O-anuli late dependet ex recta adaptatione magnitudinis O-anuli et magnitudinis sulci, quae rationabili compressione et extensione quantitatem annuli signandi efformans.

1. Cogo rate

pressio rate W vulgariter exprimitur hoc modo;

W=(d0 h)/d0× 100%

In formula, d0- diametri sectionis transversalis in libero statu O-anuli (mm);

H - Distantia inter imum sulcus anuli et superficiem signatam (profunditatem sulcam), ie crux sectionis altitudinis O-anuli post compressionem (mm)

2. Cum seligendis compressionis rationem anuli O-anuli, tres sequentes rationes considerandae sunt:

(1).Sufficere debet area contactus signandi;(2).Conare vim frictionem minuere;(3).Vitare deformatio permanens.

Non difficile est videre ex his quae inter eos sunt contradictiones.Magna pressio rate altam pressionem contactum consequi potest, at rate nimis pressio proculdubio illapsam frictionem et deformationem permanentem auget.Si rate compressio nimis parva est, potest ob errorem coaxiality et error O-anuli signandi sulcus requisitis non occurrentibus, inde in ablatione alicuius quantitatis compressionis et lacus causandi.Cum igitur rationem compressionis O-anuli eligens, necesse est varias causas ponderare.In universum, pressio rate sigillorum staticorum maior est quam sigillorum dynamicorum, at valor extremus eius minor quam 25% debet esse.Alioquin vis pressio signanter relaxat et immoderata deformatio permanentis occurret, praesertim in condiciones operationis gravissimae.Delectu compressionis ratio W pro sigillis O-anulis considerare debet condiciones usus, sicut signa static vel dynamica;Sigillum statice dividi potest in obsignationem radialem et axialem obsignationem;Lacunae hiatus sigillorum radialium (vel sigillorum stabilium cylindricorum) est hiatus radialis, dum lacus rima sigillorum axium (vel sigillorum staticorum planorum) est hiatus axialis.Sigillum axiale in duas partes dividitur secundum utrum pressionis medii agat in diametro interiore vel exteriore diametri O-anuli: pressionis internae et pressionis externae.Augmentum pressionis internae inducit ad extensionem, dum pressionis externa initialem extensionem O-anuli minuit.Variae formae statice sigillorum supra dictarum diversam partem habent actionis obsignationis medium in O-anulo, ita etiam alia ratio prae pressionis.Ad sigilla dynamica, necesse est inter sigilla motus reciproci et motus gyratorii sigilla distinguere.

(2).Static signatio: Sicut mutui machinis obsignandis, cylindricae statice machinis obsignatio plerumque capiunt W=10% ad 15%;Plana static signationem machinam accipit W=15%~30%.Ad signationem dynamicam, in tres casus dividi potest;Motus reciprocus plerumque sumitur ut W=10% ad 15%.Cum ratio compressionis ad motus gyratorias sigilla eligenda, Joule calor effectus considerari debet.Fere diametri O-anuli ad motum rotarii adhibitum est 3%-5% maior quam scapus diametri, et compressio diametri exterioris ratio W=3%-8% est.Pro frictioni ludi, O-annuli plerumque seliguntur cum ratione compressionis minoris W=5%-8% ad resistentiam frictionem reducendam.Praeterea expansio materiae iuvantis per medium et temperatum causata considerari debet.Fere, ultra pressionem deformationem datam, maximae divulgationis licita est 15%.Hoc ambitus valde indicat electionem materialem non esse idoneam, et inaures aliarum materiarum loco adhibendas esse, vel pressio deformationis data corrigi debet.

(3)Tendens quantum ,Postquam in sulco obsignando installatus est, O-anulus fere certam quantitatem extendendi habet.Sicut pressio rate, extensio etiam moles notabilis ictum in obsignatione observantiae et muneris vita O-anuli habet.Magna vis extensionis non solum difficilem efficit ut anulum O-instituat, sed etiam rate compressionem reducat propter mutationes in diametro crucis-sectionali d0, ducens ad ultrices.Extensio quantitatem exprimi potest sic:α= (d+d0)/(d1+d0)In formula, d - scapus diametri (mm);D1-- Diameter interior O-anulus (mm).Circumspectio extensionis moles 1% -5% est.Valores commendati pro extensione quantitatis O-anuli in mensa traduntur.Extensio moles O-anuli eligi potest secundum magnitudinem scapi diametri secundum modum electionis mensae.Praelatio range compressionis ratio et extensio quantum ad O-anulum

Tertia - relatio inter diametri interiorem (ID), diametri exterioris (OD), et filum diametri (C/S) ipsius O-anuli.

OD=ID+C/S*2 Ut: ID=3MM C/S=1MM OD=3MM+1*2=5MM

Quartum-Materiales communiter in productione O-annulorum

- NBR :NBR O-RING

Egregiam oleum habet resistentiam, benzenam resistentiam, resistentiam caloris, proprietates physicas et mechanicas, et una ex materia cruda communis olei cum rubber products repugnant.Late usus est in fabricandis gaskets repugnantis, gaskets, globulos hoses, mailboxes aircraft, fasciculos flexibiles, imprimendi ac tingendis globulos globulos, cables materias et adhesivas.

- EPDM:EPDM O-RING

praestantibus proprietatibus mechanicis, resistentia chemica, resistentia caloris, resistentia etiam valida exhibens.Ethylene propylene diene monomer (EPDM) praeclaras possessiones in terminis resistentiae ozonis, resistentiae caloris, resistentiae tempestatis, et mollitiem humilem ostendit, aptam faciens applicationibus ozono repugnantibus, tempestatibus resistentibus et UV resistentibus.Tamen, ob proprias structuras notas, flamma retardatio, resistentia oleum, et adhaesio EPDM Flexilis relative pauperes sunt.Nihilominus hoc genus Flexilis praecipuam catenam habet saturatam structuram et cum aliis materiis misceri potest ad meliorem perfectionem cognoscendam ab invicem viribus et infirmitatibus.

- VMQ(SILICONE);SILICONE O ANULUS

cum caloris et olei resistentia.Silicone Flexilis humilis temperaturae resistentiam bonam habet et plerumque operari ad -55 . potest℃.Post phenyl introductionem, pervenire potest -73 .℃.Calor resistentiae siliconis Flexilis etiam praestantior est, et in 180 . diu laborare potest℃.Potest sustinere plures septimanas vel plures elasticitates vel paulo supra CC℃et statim potest sustinere caliditas supra 300℃.Silicone Flexilis spirabilitatis bonum habet et permeabilitas oxygenii summa est inter polymeros synthetica.Praeterea silicone Flexilis etiam inertiae physiologicae praecipuas notas habet et coagulationem non facit, late in re medica usus.

- VITON(FKM FPM);VITON O-RING

Praeclara caloris resistentia, oxidatio resistentia, resistentia oleum, resistentia corrosio, resistentia atmosphaerica senescit, et in campis ut aerospace, aviation, autocinetum, petroleum, et adjumenta domestica late adhibita sunt.Materia clavis est quae reponi non potest in incisurae industriae defensionis nationalis

- HNBR :HNBR O-RING

resistentia boni olei (resistentia boni olei, lubricationis oleum, et menstrua aromatica);Et ob eius valde saturatam structuram, resistentiam caloris bonam habet, resistentiam chemicae corrosionis optimam (resistentiam bonam Freon, acidum et alcali), optimum ozonum resistentiam, et compressionem altam deformationem permanentem resistentiam;Eodem tempore, Flexilis nitrile hydrogenatus, etiam indoles habet ut vires altae, lacrimae resistentiae, et optimae gerunt resistentiae, unum ex praestantissimis fricatoribus in terminis comprehensivis faciendis facit.

- CR(neoprene) :CR O-RING

cum bonis proprietatibus physicis et mechanicis, resistentia olei, resistentiae caloris, resistentiae flammae, resistentiae solis, resistentiae ozonis, resistentiae acidi et alcali, et resistentiae chemicae.Incommodum est miserum frigus resistendi et stabilitatem repono.Magnam habet vim distrahendi, elongationem, crystallinitatem convertibilem, et adhaesionem bonam.Senescit et calor resistit.Optimum oleum et chemica resistentia

FVMQ: FVMQ O-RING cum Bonis proprietatibus physicis et mechanicis et stabilitate chemicis, diuturni temporis usu in CC capax.℃et brevis-terminus usus apud 250℃;Ex fragilitate iugis punctum -20℃ut -40℃;Praeclara resistentia media, optima stabilitas contra menstrua organica, acida inorganica, et oxidantes, praesertim optima resistentia acidi;Habet praeclaram tempestatem resistentia et ozono resistentia.Post aliquot annos atmosphaerae obnoxii, eius proprietates physicae et mechanicae minimum mutant, et effectus in microorganismis etiam relative stabilis est.

- FEPM(Aflas);FEPM O-RING

firmam bonam habet, resistentia chemica, praesertim resistentia ad concentrationes altorum acidarum, alcali, et agentium validorum oxidantium ad varias fuels vehiculorum genera, unguenta, olea, mineralia, et olea silicona, necnon optimam resistentiam ad pressionis aquae altae. vapor, aqua et vis electrica.Habet humilem respirabilitatem et ad temperaturae -400 et 200 gradus Celsius adhiberi potest

- FFKM:FFKM O-RING

Elasticitatem et scelerisque et chemicam stabilitatem polytetrafluoroethylene habet.Diu terminus temperatus laborantis -39~288 gradus Celsius, breve tempus usque ad 315 gradus Celsius, adhuc aliquem gradum plasticitatis habet sub aegra temperantia, dura sed non fragilis, et flecti potest.Firmum omnibus oeconomiae praeter tumorem in solventibus fluorinatis.est Currently pretiosissimum Flexilis in mundo.Brand:Kalrez

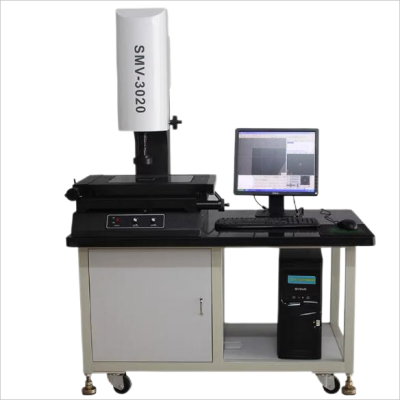

Quintum - Flexilis Anulus Specificationes Mensurae Modi ac Instrumenti.

Communia instrumenta mensurae habet :

1-Subtilitas projector

Instrumentum characteres:Mensuratio non contactu, mensurans invisibilis et apta ad partes tenuissimas et molles metiendas, validam imaginem habet munus magnificationis et parvae magnitudinis mensurae facultatem validiorem; Celeritas mensurae celeritas mensurae efficientiam valde meliorem efficit; alta densitas sampling punctorum efficit altam mensurae constantiam; Commodum clamping.

2-Electronic caliper digitalis

Instrumentum characteres:Longitudo mensurae instrumentum, quo systemata mensurae utitur, ut grides capacitivae et magneticae ad valores mensuras digitally proponendi.Communis solutionis usus est 0.01mm, cum errore licito ± 0.03mm/150mm.Etiam summus praecisio caliperarum digitalium cum resolutione 0.005mm, cum errore licito ± 0.015mm/150mm.Etiam multi propositi digitales propono micrometer caliper cum resolutione 0.001mm (quae nationalis patent instrumenta pro Anyi mensurandi et solum producere possunt), cum errore licito ± 0.005mm/50mm.Ob intuitivam et perspicuam lectionem, mensura efficientia alta est.

3-π princeps(PITAPE)

Instrumentum characteres:

1. π rector componitur ex habena chalybe elastica.Duo eius fines cum praecipuis et auxiliaribus praepositis respective insculpuntur.Valor graduatio minimi principis principalis est 0,5mm vel 1mm;Valores graduatio minimi principis auxiliaris sunt 0.02mm, 0.05mm, 0.01mm, 0.1mm, etc.

2. Cum in usu est, rectorem π involvite circa fabricam et verniorem legendi methodum utere ut recta diametri partem metiri medius legas.

- Commoda et incommoda

(1).Altus accurate: Cum diameter per circumferentiam π rectoris mensuratur, notatio erroris in productione principis reduci potest per π tempora et in eventus mensurae reflecti.Ita in φ in mensuris magnis diametri supra 500mm, accuratio eius altior est quam caliperi vernier.sede φ Haec utilitas maxime eminet in mensuris supra 1000mm.

(2).Cum partes chalybeas cum π principe metiaris, caloris operis fragmentum non afficitur.Hoc est, quia princeps π tenuissimus est, et in mensura probata erit altera pars brevissimo temporis spatio.Accedit, quod coëfficientes earum scelerisque expansio arctissima sunt, basically superans influxum temperaturae.

(3. In mensuratione magnarum et extra magnarum diametrorum, usus partium auxiliarium (pontibus magneticis patentibus) permittit ut facilem operationem per unum hominem uno tempore permittat.

(4).Partes tenues muratas metientes haud facile est ut partem operis deformet.(5).Commodum ad portandum et horreum (6).Pretium humile.

(7).Incommodum: 'non claudunt lectionem';Deviationes geometricae quales ovalitas metiri non possunt.

Sexto o anulo usus et o anulus institutionis.

1. Usus Domine anulum

O-anulus late in articulis variarum partium hydraulicarum et pneumaticorum, superficierum cylindricarum et superficierum cylindricarum adhibetur.Nam O-anuli in motu usi sunt, cum pressionis laborat maior quam 9.8Mpa et unidirectionali pressioni subiecta, anulus retentio institui debet ex altera parte O-anuli in directione pressionis;Si compressioni bidirectionali subiectae, anulum retinentem in utraque parte O-anuli pone.Ad frictionem reducendam, annuli cuneis retentis etiam adhiberi possunt.Cum pressione liquida a sinistra applicatur, anulus retinens dextrorsum impellitur, et sinistra anulus retinens superficiem signatam non attingit, ita friction vi reducendo.Super, usus retinendi annulorum attritionem vim signandi fabrica auget, et cuneum formatum annulorum retinendorum magni momenti sunt in hac frictione vi minuendo.Pro anulis fixis, annulus retentio etiam requiritur, cum pressionis laborantis maior est quam 32Mpa.

2. Oring institutionem

Institutionem qualitas O-annulorum notabilem habet ictum in obsignatione vitae perficiendi et serviendi.Quaestiones ultrices saepe causantur per institutionem pauperum. Durante processu institutionis, non licet habere anulum sculpi, misalignum, vel contortum habere.Ante ecclesiam, sulcus obsignatio et superficies coniugationis obsignatio stricte purganda est;Eodem tempore, uncto lubricandi ad superficiei applicate quae durante conventu O-ringi debet transire. Ut ne anulus O-incisus vel acutis marginibus impingatur, ut angulis ac stamina in institutione acutis, XV. ad 30º angulum plumbeum relinquendum est ad extremum stipitem et foramen finem institutionis.Cum anulus O-anulus per fila externa transire debet, dux manica metalli tenuis peculiaris ad filum externum operiendum adhibeatur;Si O-anulus necesse est ut per orificium transeat, orificium invertatur in debitam figuram diagonalem ne fricat in O-anulo.Scopuli angulus sulcus fere est = 120 º~ 140 º

Multum hinc cognitum relatis discere potes.Postea aliquam notitiam dabimusoleum signacula, sigillum hydrau;vel aliusnativus rubber partium, utCat oleum sigillum, NBR oleum sigillum, sigillum olei FKM,TC sigillum oleum, sigillum olei TB , sigillum olei TA , sigillum olei SB , sigillum olei SB ,piston sigillum, Virga sigillum ,vere sigillum ,sigillum bonded, u scyphus, sigillum, pulvis, sigillum,Wiper sigillum, anulum gestare , anulum recipere ,globulus funibus ; O funibus circulumEt ideo oportet nos hanc cognitionem ad omnes inducere.Gratias pro tempore tuo !